Prototyping

From 1 up to ...

At ARRK SPG, we can create any plastic or metal product part for testing and experimental purposes. We are especially skilled in developing Lighting applications, interior trim and modules in show cars.

CNC-Machining

- Of a wide range of plastic block materials, optical materials, including engineering plastics

- Of metals including stainless steel, aluminium and brass

- ARRK Fasttool technology for milled parts in series materials (e.g. milky, smokey)

- Block modelling (mock-up)

PU-vacuum casting

- Of a wide range of rigid and rubber-like materials

- Including 2-/3-shot casting (e.g. hard-soft combination)

- Standardized colours and surface finishing for (semi-)translucent materials

- Silicone tools based on CNC-machined masters for excellent surface quality, highest accuracy and optimum dimensional stability

- Large size castings up to max.: 2300 x 1350 x 1250 mm. (e.g. bumpers, tailgates and fenders)

- Acomon RAVolution™ PU optical clear material resistant to UV yellowing

- PU Back molding of polymer foils include in-mold structural electronics IMSE ®

Silicon casting and extrusion

- Silicone Rubbers in Shore 40A or 60A

Sheet metal cut & press

- Technical and structural parts, BIW components

- Fine electrical components such as pins and PCB strips

- Metal springs and clips

- Soft tooling and laser cutting

ARRK Global 3D-Printing

- SLS Selective Laser Sintering

- SLA Stereolithography

- Polyjet (Objet)

- DLP Technology

- DMLS / SLM Metal Sintering

ARRK Fasttool

- Block molding in series-production materials

- Various materials possible

Low Volume Production

From 50 to 2000 parts or assemblies

SPG offers high-volume quality at low quantities and cost. We cover both pre-series and niche volumes. Our special competences lie with the production of fully finished and assembled modules for the Automotive and Truck industry

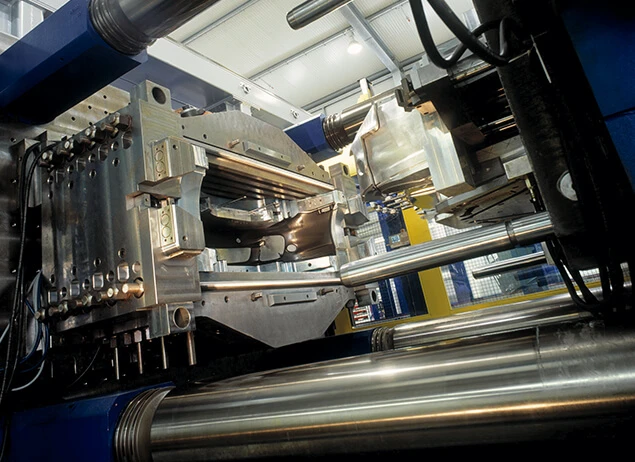

Injection Moulding

- Using aluminium moulds at ARRK SPG as well as rapid steel non-export moulds operated from our ARRK Far-East facilities

- PRE-TENSION Tool® for large mouldings

- In-Mould-Decoration (IMD) & IML/FIM with printing electronics

- Including 2-/3-shot overmoulding, gas injection (GID) and Sequential Valve Gating (SQV)

- Expandable polypropylene EPP & PUR-Foaming

Light-weight solutions

- MuCell® and Chemical foaming

- CRFP composite solutions

- Thermoplastic-prepreg overmoulding include Mitsui Tafnex™ CF-PP UD Tapes

- D-LFT Direct Long Fiber Thermoplastic moulding

Sustainable Solutions

- Using high-flow PP compounds from Mitsui Chemicals

- Using PCR and bio-based material & additives

Other solutions

- Compression Moulding (Rubber) & Liquid Silicone Rubber (LSR)

- Blow moulding

- Thermoforming

- Aluminium Sand Casting & High Pressure Die-Casting (HPDC)

- Extrusion (Aluminium, plastics and silicone rubber)

- Sheet metal (Stamping, deep drawing and pressing)

Finishing

Make it unique

In order to truly assess a product's aesthetics in the early stages of product development, it is absolutely worthwhile to build a prototype with a high-quality finish. Using various finishing techniques, we can match or surpass the quality standards of the final product.

Surface treatment and Decoration

We offer endless finishing possibilities including:

- Painting, silkscreen and pad printing

- E-coating (KTL), powder coating and anodizing

- Galvanic chrome plating

- Metallization and PVD-coating

- Flocking

- Finishing with leather, films or textiles

- And many more...

Assembly

Ready to install

Besides the production of separate parts, we can also take care of the assembly of an integrated module or even a full product. We are especially skilled in:

- Complex assemblies with multiple options, e.g. bumper facias and door panels

- Functional lighting modules including PCB’s

Welding

- Vibration Welding (friction welding)

- Hot plate welding (mirror welding)

- Ultrasonic welding

Industrial Gluing

- For all types and combinations of plastics, including surface preparation

- Metal and plastic bondings

- Adhesive tapes and kit

Project Management

Motivated to fulfill

Together with our valued partners in our supply chain, we can manage any project from A to Z. First, we map all of our customer's wishes. Next, we plan, arrange and oversee the execution and deliver the final product. This way, ARRK SPG can offer complete fulfilment, or surpass expectations.

Supply Chain & Logistics

- Sense of ownership & pro-active approach

- Strong and frequent communication

- Planning & EDI

- Packaging & RFID-Labeling

- Warehousing & Logistics

Quality Control

Finally, we execute various quality checks to make sure te products we deliver meet the highest standards.

- Parts measurement 3D CMM, tactile or digital scanning

- Process FMEA and control plan

- PPAP / EMPB & IMDS registration

Engineering Support

We help your project thrive

Together with our sister company ARRK Engineering in Germany, we can foresee in concept or series development, validation or system integration in the Automotive, Lighting and Design & Industry markets. We build upon the extensive knowledge of our partners, while coordinating the process for our customers.

Interdisciplinary Topics

Because both ARRK SPG and ARRK Engineering possess a rich knowledge base, we can give thorough advice on interdisciplinary topics like Electronics & Software, CAE, Material, Acoustics and Composite for Automotive purposes. In the Lighting area, ARRK Engineering can help in the interdisciplinary development, testing and integration of optical systems.

Modules

Whether it concerns a Car Body, Powertrain, Optical Systems, Lighting Systems, Chassis or Interior & Exterior parts, together with our partners of ARRK Engineering, we can shape any Automotive or Lighting element.

Entire Vehicle Systems

Regardless of a product's complexity, ARRK Engineering always helps your project thrive. Entire Vehicle Systems is one of their topics of focus, including Passive Safety and Thermal Management.